Lamination Stack Prototyping

Lamination Stack Prototyping

Lamination stacks are critical elements for medical devices, guidance systems, defense vehicles, and more. To ensure these components will perform optimally in a specific application before mass production, TLC provides lamination stack prototyping services based on each customer's unique needs. Whether your applications require something standard or highly unique, we can accommodate nearly any request. Our prototyping services are available in short, medium, and long volume orders.

At TLC, the prototyping process begins with alloy selection. Our experts can help you identify a material that meets all your performance and cost requirements. After selecting the most effective alloy, we can either stamp, notch, or laser-cut the laminations, depending on order volume. We then make stacking fixtures to hold the laminations while they are stacked to the desired height, with a tolerance of +/- 1 lamination. Precision gauge pins accurately align each stack up to +/- 0.0001 in. Finally, we bond, rivet, or weld the laminations together, depending on application requirements.

Metals Used in Our Lamination Stack Prototyping

Lamination stacks from TLC can be made from several metal options depending on the needs of the end application and cost restraints. Some of the most popular metals are nickel-based and cobalt-based. Nickel alloys feature low core losses and high permeability at low to moderate inductions, making them well suited to motor components. Cobalt offers numerous benefits, including improved corrosion and heat resistance.

Lamination stacks made with cobalt-iron or nickel-iron are cost-effective, offering excellent wear resistance in heavy-duty applications such as those within the aerospace and military industries.At TLC, we can produce cobalt and nickel-iron laminations as thin as .004 in. thick, which is important for providing optimal resistance to eddy current losses.

At TLC, we also produce laminations from silicon steel and thin-gauge electrical steel. Silicon steel is ideal for electrical components such as generators, pulse transformers, or small relays. Thin-gauge electrical steel is well suited for high-performance applications and meeting energy efficiency requirements.

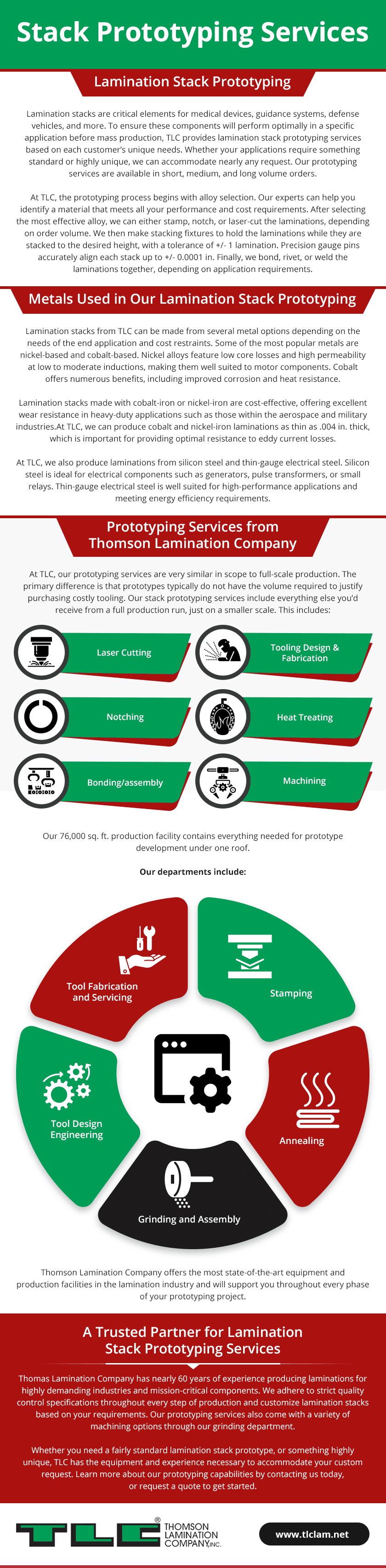

Prototyping Services from Thomson Lamination Company

At TLC, our prototyping services are very similar in scope to full-scale production. The primary difference is that prototypes typically do not have the volume required to justify purchasing costly tooling. Our stack prototyping services include everything else you'd receive from a full production run, just on a smaller scale. This includes:

- Laser cutting

- Wire cutting

- Notching

- Heat treating

- Bonding/assembly

- Machining

Our 76,000 sq. ft. production facility contains everything needed for prototype development under one roof. Our departments include:

Thomson Lamination Company offers the most state-of-the-art equipment and production facilities in the lamination industry and will support you throughout every phase of your prototyping project.

A Trusted Partner for Lamination Stack Prototyping Services

Thomas Lamination Company has nearly 60 years of experience producing laminations for highly demanding industries and mission-critical components. We adhere to strict quality control specifications throughout every step of production and customize lamination stacks based on your requirements. Our prototyping services also come with a variety of machining options through our grinding department.

Whether you need a fairly standard lamination stack prototype, or something highly unique, TLC has the equipment and experience necessary to accommodate your custom request. Learn more about our prototyping capabilities by contacting us today, or request a quote to get started.