Journeyman Apprenticeship Completions

The United States Department of Labor Machine One course from Camden County College focuses on CNC, manual, mill, and lathe machining. It involves 2,000 hours of on-the-job training and online academic Related Technical Training (RTI). After completing the RTI, apprentices receive a 13-credit Academic Certificate in Precision Machining Technology (PMT).

Thomson Lamination Company, Inc. (TLC®) is proud to sponsor the US Department of Labor’s Journeyperson Apprenticeship Program. We support our employees in their endeavors to complete the PMT curriculum and advance their skills. Here, we’ll explore the Precision Machining Technology program, including its curriculum, the skills it builds and certifies, and our graduates from the program.

Precision Machining Technology (PMT) Curriculum

The PMT curriculum is a 13-credit Academic Certificate consisting of the following courses:

- CIM-101 Machine Shop Practices (3 credits)

- CIM-221 CNC Programming & CAM (4 credits)

- CIM-202 Conventional Machinist (3 credits)

- CIM- 219 CNC Machinist (3 credits)

All 13 credits earned from this curriculum can be directly applied to an Associate of Applied Science in Computer Integrated Manufacturing. The program provides apprentices with the following National Institute of Metalworking Skills (NIMS) certifications:

- Measurement, Material, & Safety

- Job Planning & Bench Work

- Drill Press

- Manual Mill Lathe Work & Chucking

- Lathe Work

- Turning between Centers

- CNC Mill & Set-up Operation

- CNC Lathe Set-up & Operation

- CNC Mill Programming

- CNC Lathe Programming

- Surface Grinding

Employees That Have Earned Their PMT Certificate

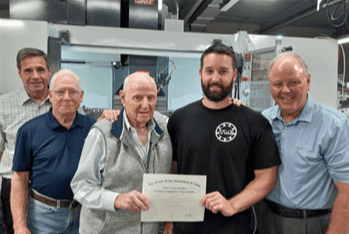

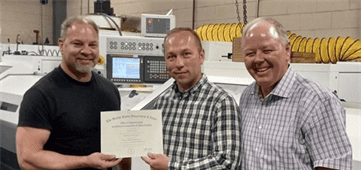

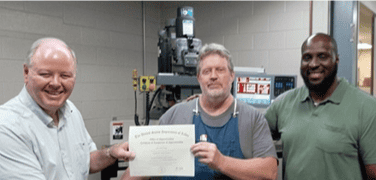

In addition to sponsoring the US Department of Labor’s Journeyperson Apprenticeship Program, TLC has had 4 employees graduate and receive their Apprenticeship Certificate in the past year. These employees include:

Pictured below: Kyle Atchison, Tool Room Engineer and Apprentice Graduate (center); Jeff Geckle, Tool and Die Maker and mentor (left); Sterling A. Martin III, President (right).

Pictured below from left to right: Dan O’Connor, Director of Quality; John McGovern, Tool Room Supervisor; Sterling A. Martin, CEO and Owner; Zachary More, Tool Maker II and Apprentice Graduate; Sterling A. Martin III, President.

Pictured below: John Darhun, Grinding Operator and Apprentice Graduate (center); Paul Barton, Grinding Department Supervisor and mentor (left); Sterling A. Martin III, President (right).

Pictured below: Bruce Anlage, Senior Machinist and Apprentice Graduate (center); Sterling A. Martin III, President (left); Jerry Brioche, Special Projects Manager (right).

Why Choose TLC

The PMT curriculum offered by Camden County College is an academic course that provides apprentices with several NIMS-certified skills, including CNC mill and lathe operation, setup, programming, and much more. By mentoring and supporting our employees as they complete this program, TLC® fosters a work environment focused on skills development and career growth.

Thomson Lamination Company is a state-of-the-art specialty lamination stamping company that utilizes high alloy materials. We also offer high-temperature annealing and assembly services in controlled nitrogen and hydrogen atmospheres. We specialize in manufacturing high-end and niche-market stamped laminations that adhere to very tight tolerances for use in mission-critical rotating parts. Our products are annealed at high temperatures in a controlled atmosphere to ensure optimal performance.

Contact us to speak with a team member about the advantages of choosing TLC® for your next machining project.