At Thomson Lamination Company (TLC), we are a premier manufacturer of stamped motor lamination components. We can produce prototypes to high-volume production quantities of rotor and stator laminations from high-conductivity metals to tight tolerances.

What Are Motor Laminations?

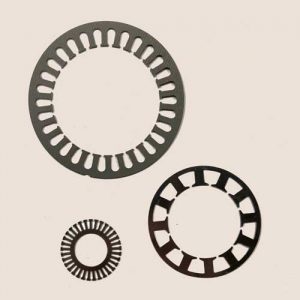

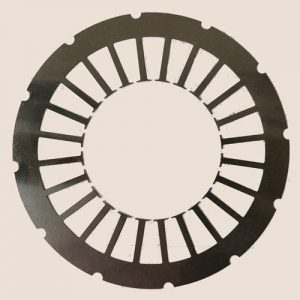

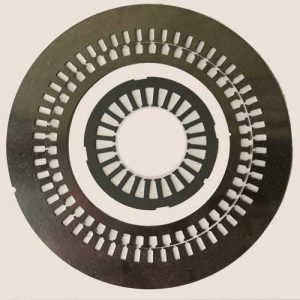

Motor laminations form the core of an electric motor’s stator and rotor. They consist of thin metal sheets that are stacked, welded, or bonded together. By making them from individual pieces of metal rather than a solid pieces, they experience less eddy current losses.

Our Motor Lamination Materials

Our motor lamination experience allows us to use a variety of materials to stamp out motor laminations, such as:

- Cobalt. Cobalt-iron alloys offer a number of benefits when used in stamped components, including improved resistance to corrosion, heat, and wear. We offer Hiperco 50 and Vacodur 49 for motor laminations.

- Nickel alloy. Nickel alloys are highly suitable for motor components due to their high permeability at low to moderate inductions and low core losses. We can work with the following types: HiPerm 49, HyMu 80, Permenorm 5000 V5, ULTRAVAC 80, VDM MAG 50, and VDM MAG 7940.

- Silicon steel. Silicon steel—also called electrical steel—exhibits excellent electrical conductivity, making it ideal for electrical components like generators, motors, pulse transformers, and small relays. We offer the following grades for our motor laminations: M15, M19, M22, M27, M36, and M45.

- Thin-gauge electrical steel. Thin-gauge electrical steel is ideal for applications with high performance and energy-efficiency requirements. Some of the types we use for our motor lamination projects include Sura and Arnon

We can stamp motor lamination from materials ranging in thickness from 0.003 to 0.025 inches to extremely tight tolerances. Our capabilities are as follows:

- Cobalt: 0.004 to 0.020 inches

- Nickel alloy: 0.004 to 0.020 inches

- Silicon steel: 0.014 to 0.025 inches

- Thin-gauge electrical steel: 0.003 to 0.010 inches

Our Motor Lamination Stamping Capabilities

Our 76,000 sq. ft. facility houses a variety of high-speed presses with capacities of up to 250 tons and the capability of running dies up to 36 inches by 72 inches in size as well as an extensive catalog of over 1,500 dies. This equipment enables us to stamp motor laminations in the full round from 0.5 inches OD to 15 inches OD for use in core assemblies. If the customer has highly specific or unique requirements and restrictions, we can design and build proprietary dies that suit their exact needs, whether the project calls for dedicated carbide progressive dies or master insert dies.

In addition to our metal stamping capabilities, we also offer in-house annealing, grinding, assembly, and other post-stamping services to ensure we can deliver complete motor lamination fabrication solutions. Once the thin lamination sheets are stamped, we stack them by bonding, welding, riveting, or staking them in the die to form core assemblies. After the completion of the project, we store each die physically and digitally to ensure we can quickly manufacture more pieces when they are needed.

Your Product. Our Precision. That’s TLC.

Whether you need standard or unique motor laminations, TLC can handle your requirements. Our 57+ years of experience and equipment enable us to accommodate nearly any custom request, whether you need a particular die design, a specific material, special annealing requirements, or precise tolerances. That’s why customers across a wide range of industries—aerospace, energy, machine tool, medical, and military—know they can trust us to deliver motor laminations that meet their specifications and quality standards.

Contact us today to learn more about our motor lamination capabilities. Request a quote to get started on your solution or project.