When converting electrical energy to mechanical energy, eddy current loss is common. Too much eddy current loss can result in core power loss. Lamination stacks will suppress eddy current losses and regulate energy. Read on to learn more about lamination stacks and the benefits they offer.

What Are Lamination Stacks and How Are They Made?

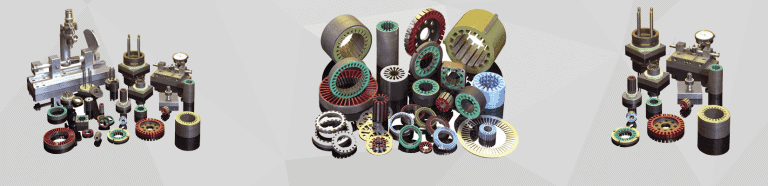

Lamination stacks are often used as stators or rotors in generators or electric motors. They can also be used as laminated cores. Lamination stacks are often made with nickel-iron or cobalt-iron materials to optimize costs and wear resistance. Both nickel- and cobalt-based materials are ideal for lamination stacks because they perform well in critical, heavy-duty applications, such as automotive, aerospace, and military settings.

Once you decide on an alloy, the laminations are laser-cut, notched, or stamped for precision, depending upon volume. Stacking fixtures are made to hold the laminations, which are then stacked to the correct height, with a tolerance of +/- 1 lamination. Precision gauge pins align each stack with accuracy up to +/- 0.0001 inches. Once the laminations are placed onto a stacking fixture, the laminations can be welded, riveted, or bonded together, depending on the application.

What Are Some Benefits of Using Lamination Stacks?

Our cobalt and nickel-iron laminations can be as thin as .004 inches thick. This dimension is important because thinner layers have better resistance to eddy current losses. Without lamination stacks, eddy currents can generate so much heat, causing poor performance and potential motor failure.

Thomson Lamination Company ensures strict quality control, from raw materials through ready-to-use stacks. Our lamination stacks are essential elements in generators for aerospace, defense vehicles, medical devices, guidance systems and more. We help you customize your lamination stacks based on the specific materials or limitations required by your application. We can also create prototypes for your approval before mass-producing them for your project. Additionally, we offer a variety of machining options through our Grinding Department.

Reliable, High-Quality Lamination Stacks from Thomson Lamination Company

Lamination stacks are vital components in electric motors, generators, vehicles, and other electromechanical systems. Thomson Lamination’s cobalt and nickel-iron laminations are highly effective at limiting eddy current losses and optimizing the efficiency of any system.

We have years of experience producing lamination stacks for a variety of applications. We would be happy to work with you to find the best type of lamination and stack to fit your needs. If you’re ready to begin, contact us today or request a quote.

Posted in Lamination Stacks