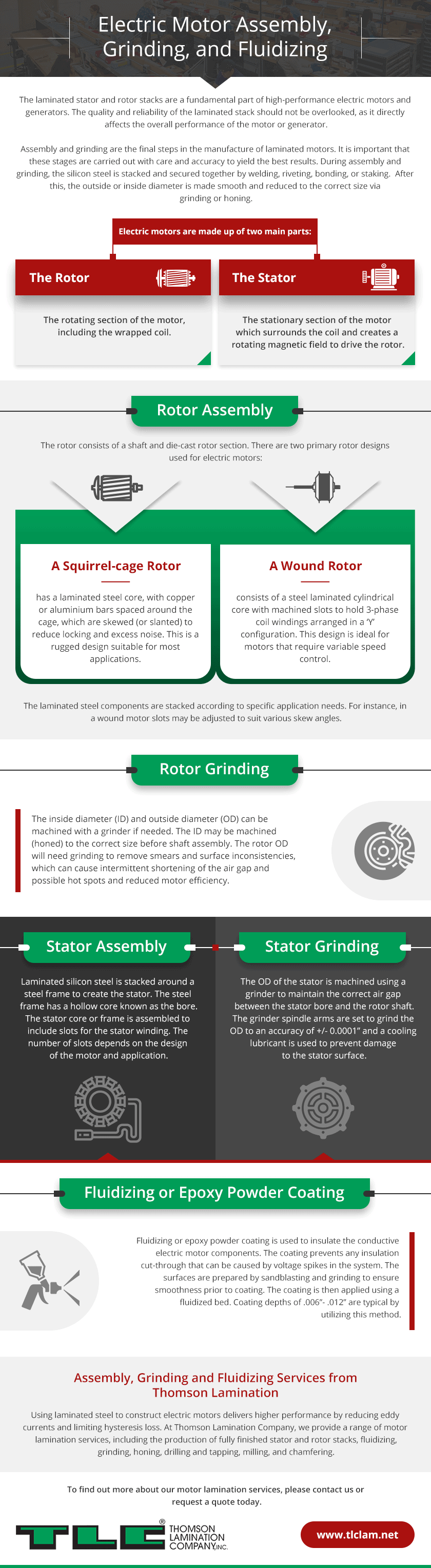

The laminated stator and rotor stacks are a fundamental part of high-performance electric motors and generators. The quality and reliability of the laminated stack should not be overlooked, as it directly affects the overall performance of the motor or generator.

Using laminated steel to manufacture electric motors helps to reduce eddy currents, which in turn increases the power output of the motor. Laminated silicon steel (also known as electrical steel) also helps to reduce hysteresis loss, which means that the generation of the electromagnetic field in the motor is more efficient.

Assembly and grinding are the final steps in the manufacture of laminated motors. It is important that these stages are carried out with care and accuracy to yield the best results. During assembly and grinding, the silicon steel is stacked and secured together by welding, riveting, bonding, or staking. After this, the outside or inside diameter is made smooth and reduced to the correct size via grinding or honing.

Electric motors are made up of two main parts:

· The rotor: The rotating section of the motor, including the wrapped coil.

· The stator: The stationary section of the motor which surrounds the coil and creates a rotating magnetic field to drive the rotor.

Rotor Assembly

The rotor consists of a shaft and die-cast rotor section. There are two primary rotor designs used for electric motors:

· A squirrel-cage rotor has a laminated steel core, with copper or aluminium bars spaced around the cage, which are skewed (or slanted) to reduce locking and excess noise. This is a rugged design suitable for most applications.

· A wound rotor consists of a steel laminated cylindrical core with machined slots to hold 3-phase coil windings arranged in a ‘Y’ configuration. This design is ideal for motors that require variable speed control.

The laminated steel components are stacked according to specific application needs. For instance, in a wound motor slots may be adjusted to suit various skew angles.

Rotor Grinding

The inside diameter (ID) and outside diameter (OD) can be machined with a grinder if needed. The ID may be machined (honed) to the correct size before shaft assembly. The rotor OD will need grinding to remove smears and surface inconsistencies, which can cause intermittent shortening of the air gap and possible hot spots and reduced motor efficiency. TLC can guarantee ID and OD tolerances to +/- 0.0001”, and OD to ID concentricity can be held to 0.0001” even on delicate, flexible stacks with thin wall sections. Our state-of-the-art inspection equipment enables us to verify concentricity and roundness to an accuracy of 30 millionths of an inch.

Stator Assembly

Laminated silicon steel is stacked around a steel frame to create the stator. The steel frame has a hollow core known as the bore. The stator core or frame is assembled to include slots for the stator winding. The number of slots depends on the design of the motor and application.

The laminations are usually around .014” thick and are selected for their mechanical properties, core loss values, and magnetic properties. Assembly of the laminations involves stacking them in an overlapped configuration and clamping axially using key bars or tie bolts that penetrate the core.

Stator Grinding

The OD of the stator is machined using a grinder to maintain the correct air gap between the stator bore and the rotor shaft. The grinder spindle arms are set to grind the OD to an accuracy of +/- 0.0001” and a cooling lubricant is used to prevent damage to the stator surface.

Fluidizing or Epoxy Powder Coating

Assembly, Grinding and Fluidizing Services from Thomson Lamination

Using laminated steel to construct electric motors delivers higher performance by reducing eddy currents and limiting hysteresis loss. At Thomson Lamination Company, we provide a range of motor lamination services, including the production of fully finished stator and rotor stacks, fluidizing, grinding, honing, drilling and tapping, milling, and chamfering.

To find out more about our motor lamination services, please contact us or request a quote today.