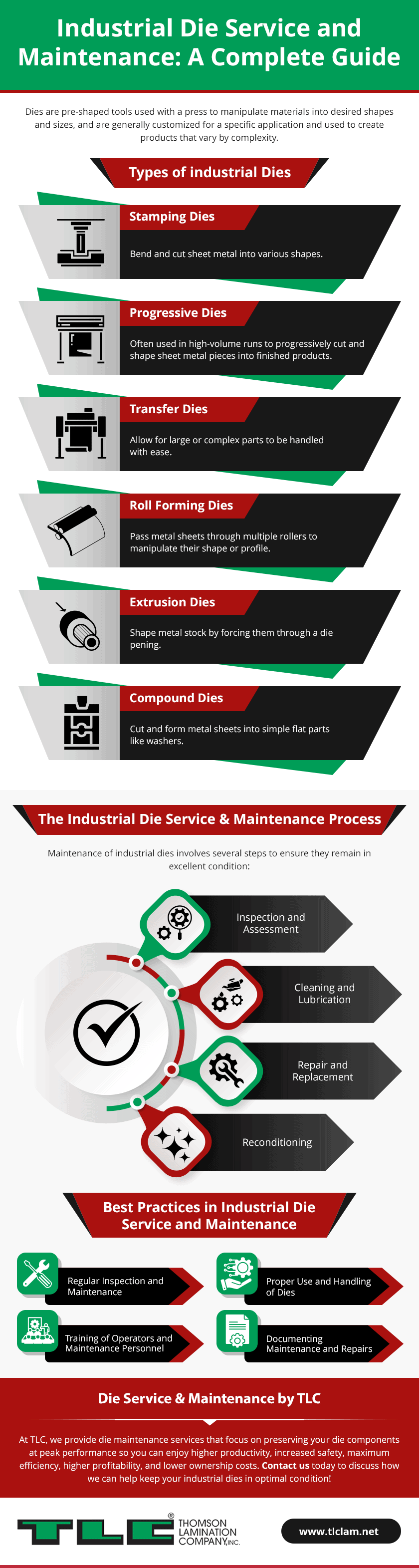

Industrial Die Service and Maintenance: A Complete Guide

About Industrial Dies

Industrial dies are important tools in the manufacturing industry, so keeping them properly maintained is key to maximizing their efficiency, safety, and longevity. Dies are pre-shaped tools used with a press to manipulate materials into desired shapes and sizes. Similar to molds, dies are generally customized for a specific application and used to create products that vary by complexity. This article outlines the various types of industrial dies, the importance of die maintenance, and how best to maintain them to prevent costly downtime and extend their lifespan.

Types of Industrial Dies

There are several types of industrial dies, each designed for a specific application and differentiated by the techniques required to produce the end component. Here are the most common ones:

- Stamping Dies: These dies bend and cut sheet metal into various shapes. There are many kinds of stamping dies, all of which perform a few basic operations—cutting, forming, or both. The die is typically made from tool steel, carbide, or other hard, wear-resistant materials.

- Progressive Dies: These are often used in high-volume runs to progressively cut and shape sheet metal pieces into finished products. The metal workpiece travels through multiple stations of the progressive die, with each station performing a certain operation until the part is complete. In the end, the individual finished parts are separated from the metal sheet. Progressive dies have high production rates, lower labor costs, and require less punching force.

- Transfer Dies: Similar to progressive dies, transfer dies also use a series of stations to perform specific operations. The only difference is that the metal workpieces are blanked first into individual pieces before they move through the die. Transfer dies allow for large or complex parts to be handled with ease.

- Roll Forming Dies: Roll forming dies pass metal sheets through multiple rollers to manipulate their shape or profile. Each roller makes an incremental change to the sheet metal until the desired profile is achieved.

- Extrusion Dies: Extrusion dies shape metal stock by forcing them through a die opening. The die is a thick, circular steel disk (usually H13 steel) with an opening the shape and size of the intended cross-section of the final extruded product.

- Compound Dies: Compound dies cut and form metal sheets into simple flat parts like washers. Since compound dies can perform multiple operations like cutting and punching in a single stroke, they’re highly effective in manufacturing high-volume parts.

The Industrial Die Service & Maintenance Process

Maintenance of industrial dies involves several steps to ensure they remain in excellent condition:

- Inspection and Assessment: This can identify minor issues before they turn into costly repairs. It involves visual inspection, dimensional measurement, non-destructive testing (NDT), and wear and damage assessment. Inspect your dies for loose screws and fasteners, broken components, galled die sections, and missing dowel pins.

- Cleaning and Lubrication: Dirt, debris, and other FOD ( Foreign objects and debris) can quickly accumulate on industrial dies, leading to corrosion, rust, and other forms of wear. Friction can also cause the dies to break down. Clean out any dirt and debris that may have accumulated, and check your dies’ lubrication levels.

- Repair and Replacement: This step involves replacing or repairing worn-out or damaged components. Repairs may include surface treatment, welding, or finishing. Replace parts if they cannot be repaired.

- Reconditioning: By restoring the die to its original condition (or even better), reconditioning may involve polishing, grinding, and/or heat treatment, which can extend the dies’ lifespan and save money long-term.

Best Practices in Industrial Die Service & Maintenance

Here are some best practices to properly maintain your industrial dies:

Regular Inspection and Maintenance: Inspecting and maintaining your dies regularly can help you spot any potential issues before they become more serious problems. Routine inspections are simple yet highly effective ways to reduce instances of failure and unplanned downtime.

Proper Use and Handling of Dies: Handle and use the dies properly to prevent premature wear or damage.

Training of Operators and Maintenance Personnel: Damage to equipment or physical injury to employees often occurs due to a lack of knowledge. Properly training operators can help prevent accidents and ensure maintenance is performed correctly.

Documenting Maintenance and Repairs: Keeping a log of all die maintenance and repairs can help you monitor the dies’ performance and identify potential areas of concern.

Die Service & Maintenance by TLC

Die maintenance ensures your equipment is in top shape, reducing downtime and expensive repairs. Proper maintenance involves regular inspections, cleaning, lubrication, and reconditioning, but in a busy manufacturing environment, it can be easy to overlook or forget these essential maintenance tasks.

At TLC, we provide die maintenance services that focus on preserving your die components at peak performance so you can enjoy higher productivity, increased safety, maximum efficiency, higher profitability, and lower ownership costs. Contact us today to discuss how we can help keep your industrial dies in optimal condition!